Car Park Solutions

CO Sensor Controllers

Car Park Extraction of Carbon Monoxide

Our range of carbon monoxide (CO) and nitrogen dioxide (NO2) car park sensors and controllers, combined with the ABC FC4 fast fit DIN mount car park fan switching module is excellent for small to large car parks. As well as our fast fit DIN mount control modules for auto/off/man with run fail lamps, lamp test, alarm control and high signal select. Put it all together to make a great system that will save hours in labour.

The SEN TGW-AC series is a wall mount carbon monoxide sensor/controller used in the car park emission sensing and control systems required by regulations for new buildings. Joining it is the new TGW-AN NO2 controller and TGW-ACN combined CO/NO2 controller

Senva sensors and AB Controls systems are designed to more than comply with Australian standards. Each Senva controller has two programmable relay outputs and two analogue outputs. Each sensor has a built-in audible and visual alarm and a digital read-out showing the CO concentration level so you know which sensor has triggered and why. Every sensor is designed to operate stand-alone so there is no need for an expensive central controller and each one is designed so that a number of sensors can be connected together for a larger system.

For a complete AS1668 compliant car park control system you can now add our new ABC FC4 fast fit DIN mount switch module which give you easy connections to your variable speed drive (VSD), CO controllers, auto/off/man switch, run/fail lamps and fire indication panel (FIP) and takes hours off the time to build a car park Mechanical Services Control panel.

If you are looking for a complete electrical design for a specific site, system commissioning or yearly recalibration of sensors please contact us or the AB Controls agent in your state.

Specific information taken from AS1668.2 for car park exhaust systems

The following information is interpreted from AS1668.2 2012 and is subject to change at any time by Australian standards. This information is not intended to replace or be used instead of any current Australian standards. Reference must be made to current standards for exact information. Places that must be ventilated include but may not be limited to the following:

Car parks that come under the guidelines of AS1668 for mechanical ventilation.

Areas apart from car parks that need to be ventilated including enclosed driveways, loading docks, auto service and repair shops and areas with special purpose vehicles such as fork lift trucks that run on LPG, diesel or petrol.

Areas where vehicles queue with engines operating for any reason must be ventilated.

Auto lifts need ventilation at least 2000 L/s unless they have open sides and no ceiling.

The above areas must be ventilated at the FVR (full ventilation rate) unless a contaminant monitoring system is used and the monitoring system must comply with As1668 requirements. This is where Senva and AB Controls come in.

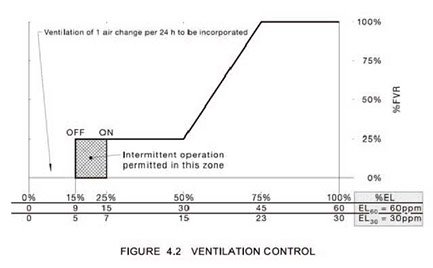

For a standard car park where people just park their car and leave, the exposure rate is 60ppm (parts per million). For a place where people have to work or be exposed for longer than one hour (staffed car park), the exposure rate is 30ppm, these include attended car parks and sections where car detailing is done. When a contaminant monitoring system is used, the ventilation rate can be varied, saving on running costs. Australian standards at the time of writing allow for varied ventilation rates according to specific requirements as shown above. Please note that this chart relates to % of air flow, not % of fan speed, so when installing a system you must obtain the fan curve chart for the fam you are using or use direct air flow measurement with suitable instruments to determine the ventilation rates.

For car parks with fewer than 40 car spaces, the rules are similar when used with a contaminant monitoring system, however the system is allowed to shut down when the car park is not occupied for more than 2 hours but must restart if any one enters the car park area. Because this requires sensors for every door, lift and possibly motion sensors as well, it may be better to use the above chart that allows for the fans to be down to 1 air change in 24 hours. However, slowing the fan down to one air change per 24 hours may cause problems with the fan or VSD, it may be better at the design stage to incorporate an additional small fan that will run at full speed all the time at the equivalent of 1 air change per 24 hours.

Sensor Mounting

No part of the monitored space should be more than 25m away from a sensor so mark out a 25m radius around each sensor and remember not to miss out the corners. The sensors should be located between 750mm and 1800mm above the floor surface as per AS1668.2. personally I prefer to keep them at the average head height as this is the air we breathe. Additional detectors are expected to be provided where people congregate such as waiting areas.